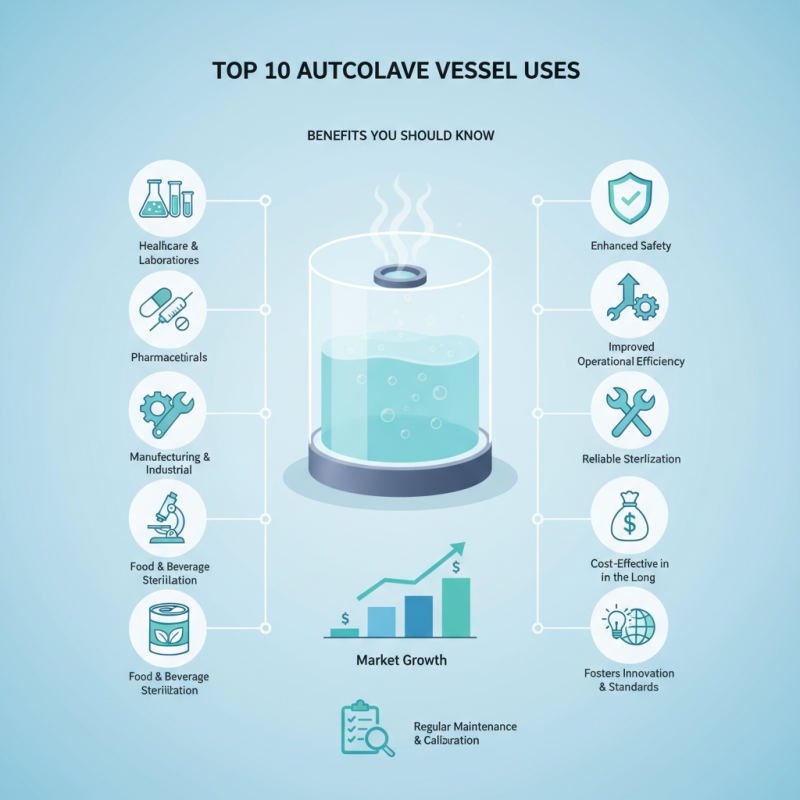

Top 10 Autoclave Vessel Uses and Benefits You Should Know?

The Autoclave Vessel is a vital component in many industries, significantly impacting efficiency and safety. According to a report by MarketsandMarkets, the global autoclave market is projected to reach $2.2 billion by 2025, underlining its growing importance. This device sterilizes various materials using high-pressure steam, proving essential in healthcare, pharmaceuticals, and manufacturing sectors.

Dr. Emily Chen, an expert in sterilization technologies, has noted, “Autoclave vessels not only ensure safety but also enhance operational efficiency.” Many companies rely on autoclave vessels for effective sterilization, yet some still overlook their maintenance. Regular checks and calibration can prevent serious operational issues.

Understanding the uses and benefits of autoclave vessels can lead to better practices. These vessels improve product safety. However, the initial investment and operational training can be challenging for some organizations. Recognizing the importance of these vessels can foster a culture of safety and innovation.

Overview of Autoclave Vessels: Definition and Functionality

Autoclave vessels play a critical role in various industries. These pressurized chambers use steam or hot water to sterilize equipment and materials. The functionality is straightforward: the heat and pressure eliminate contaminants effectively. According to industry reports, the global autoclave market is expected to reach $4 billion by 2026. This reflects a growing reliance on autoclaves for safety and efficiency.

In the medical field, autoclaves are indispensable. Hospitals depend on them to sterilize surgical instruments and lab equipment. A well-maintained autoclave can achieve sterility assurance levels of 10-6, which is crucial for patient safety. However, not all facilities adequately monitor their autoclave performance. Inadequate maintenance can lead to failures, risking contamination.

Beyond healthcare, autoclaves serve in aerospace, food processing, and pharmaceuticals. They help in manufacturing complex components with precision. A study by the American Society for Testing and Materials indicated that 25% of manufacturers reported insufficient training on autoclave operations. This gap can undermine their effective use. Organizations must address this knowledge deficit to ensure safety and compliance.

Common Industrial Applications of Autoclave Vessels

Autoclave vessels are essential in various industries, offering significant benefits. These pressure vessels play a crucial role in processing materials with heat and pressure. One common application is in the aerospace sector, where they cure composite materials. High temperature and pressure ensure the strength of components used in aircraft.

In the medical field, autoclaves sterilize surgical instruments. They effectively eliminate pathogens, ensuring safety and hygiene. Laboratories also utilize autoclave vessels for sterilizing equipment and media. This process is vital for research and experimentation, reducing contamination risks.

Tips: Maintain the autoclave regularly. This ensures optimal performance and safety. Always follow the manufacturer's guidelines. Keep records of maintenance and usage. It can help identify trends or issues early.

Autoclaves also serve the automotive industry. They help in producing lightweight structures for vehicles. However, if not monitored closely, potential issues like temperature inconsistencies may arise. Regular calibration can mitigate this risk. Be aware of how crucial precise conditions are during the curing process.

Overall, understanding the diverse applications of autoclave vessels highlights their importance in industrial settings.

Key Benefits of Using Autoclave Vessels in Healthcare

Autoclave vessels play a crucial role in healthcare settings. They provide a safe and efficient way to sterilize medical instruments. This process eliminates bacteria, viruses, and spores. The high temperature and pressure create an environment that is deadly for pathogens. Hospitals heavily rely on this technology to ensure patient safety and uphold hygiene standards.

Using autoclaves can boost operational efficiency. Staff can prepare instruments quickly after sterilization. This reduces wait times in surgical procedures. Moreover, autoclave vessels are versatile; they can handle various materials like glass, metal, and certain plastics. However, there’s a learning curve. Operators must be trained to avoid errors that can compromise sterilization. Regular maintenance is key; a poorly maintained autoclave can lead to ineffective sterilization.

The environmental impact of autoclave vessels is noteworthy. While they reduce waste from disposables, they consume energy. Hospitals should monitor energy usage and look for improvements. Balancing efficiency with eco-friendliness is essential. Autoclave vessels can be highly beneficial, but there is always room for reflection and enhancement in their use.

Top 10 Autoclave Vessel Uses and Benefits You Should Know

| Use/Benefit | Description |

|---|---|

| Sterilization | Effectively kills bacteria, viruses, and spores |

| Medical Instrument Sterilization | Used for sterilizing surgical instruments before use |

| Laboratory Equipment Sterilization | Cleans and sterilizes glassware and lab tools |

| Culture Media Preparation | Prepares sterile media for microbiological cultures |

| Pharmaceutical Manufacturing | Ensures sterility in drug production processes |

| Research Applications | Used in various research fields requiring sterilization |

| Dental Practices | For sterilizing dental tools and equipment |

| Veterinary Medicine | Sterilizes instruments used in animal care |

| Environmental Monitoring | Sterilizes samples for environmental testing |

| Disposal of Biohazard Waste | Safely disposes of biohazardous materials |

Autoclave Vessels in Laboratory Research: A Versatile Tool

Autoclave vessels are essential in laboratory research. They create high-pressure steam environments for sterilization and material preparation. Researchers use these vessels for various applications, including microbiological testing and material durability studies. They ensure that experiments are conducted in a sterile and controlled environment.

Tips: Always check the condition of your autoclave seals. Leaky seals can compromise sterilization. Regular maintenance is crucial for optimal performance.

In addition to sterilization, autoclaves can be used in polymer processing. Scientists explore new materials in controlled conditions. This versatility opens up numerous avenues for experimentation. Yet, some researchers overlook the importance of proper calibration. An improperly calibrated autoclave can lead to disastrous results.

Tips: Calibrate your autoclave vessel regularly for accurate results. Double-check the pressure and temperature settings before each use. Don't rush this critical step.

Top 10 Autoclave Vessel Uses and Benefits

This bar chart illustrates the various uses of autoclave vessels in laboratory research. The data represents the percentage of laboratories that utilize autoclave vessels for specific applications.

Environmental Benefits of Autoclave Vessels in Waste Management

Autoclave vessels play a vital role in waste management. These units use high-pressure steam to sterilize and treat various types of waste. They remove harmful pathogens and contaminants effectively, helping to protect the environment. A cleaner ecological footprint is a significant benefit.

Moreover, these vessels can reduce landfill waste. By converting waste into safe materials, we minimize what ends up in landfills. However, the process isn't perfect. Scheduling and maintenance can be challenging. Sometimes, not all waste types can be treated effectively. This limitation raises questions about efficiency.

Despite these concerns, the environmental benefits are substantial. Autoclave vessels can transform waste into reusable resources. This process aligns with sustainable practices, reducing reliance on fossil fuels and virgin materials. Investing in advanced technology could enhance efficiency even further. As with any technology, continuous improvement is essential. It is crucial to address these challenges to maximize the benefits of autoclave vessels in waste management.